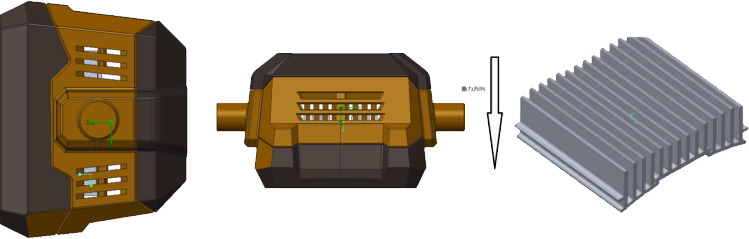

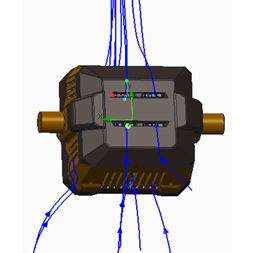

Natural cooling is a type of cooling approach that is in common use. It utilizes the high thermal conductivity of materials (mostly extruded materials) to carry heat away and dissipate the heat to the ambient air.

Even if there is no specific airflow speed requirement, it is still feasible to realize the cooling of a product by using natural cooling heat sinks which are made by copper-aluminum cooling plates, aluminum extruded parts, machined parts or die-casting alloys.

Winshare Thermal has been focusing on high power cooling and we have seen some breakthroughs for our natural cooling technology from our own research in recent years.

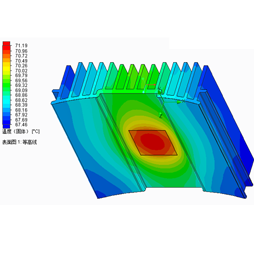

For example, we independently developed high-density skived-fin technology to realize the ultrathin fins, ultra small gaps, and high aspect ratio for the production of the main structure of our heat sinks. This technique can comprehensively replace the current stitched fin technique since it has the advantages of larger cooling area, one-step forming, 100% thermal conductivity of the material, higher cooling performance. On the innovation of techniques of heat sink materials, we have adopted the most advanced friction welding technique in order to resolve the technical bottleneck of extruded materials that cannot meet the requirement of ultra wide cooling structure. We have successfully realized larger cooling capacity and made breakthrough in larger cooling structures, etc.

Technical innovation is the cornerstone of Winshare Thermal's long-term development. Via in-depth investigation on the natural cooling techniques, we realized higher cooling performance. Meanwhile, we have been using our new techniques to provide our clients with better and optimized cooling solutions and have been widely acclaimed by clients from various industries.

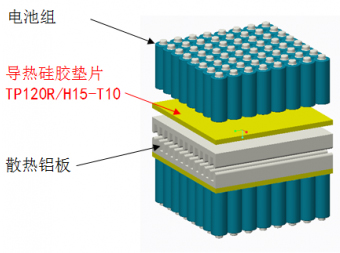

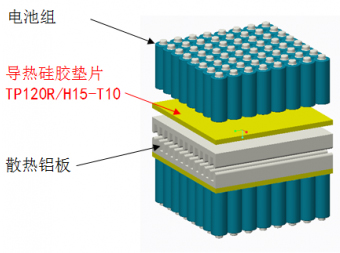

Winshare Thermal's natural cooling heat sinks have been widely used in different fields including cooling of medium-to-high voltage inverters, cooling of solar energy storage, cooling of power batteries, cooling of electric motors for rail traffic, etc.

Cooling by extruded materials: aluminum extruded heat sinks, aluminum alloy heat sinks, copper-aluminum composite heat sinks

Cooling by material joining techniques: friction welding heat sinks, stacked fin heat sinks, stitched fin heat sinks

Cooling by skived fin techniques: skived fin heat sinks, aluminum skived fin heat sinks, copper skived fin heat sinks

Cooling by forging techniques: cold forging heat sinks, sunflower heat sinks

Cooling by machining techniques: machined heat sinks, lathed aluminum heat sinks, lathed copper heat sinks

Cooling by die-casting techniques: die-casting heat sinks, casting heat sinks

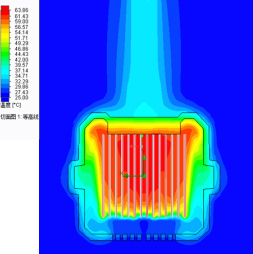

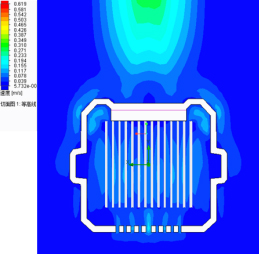

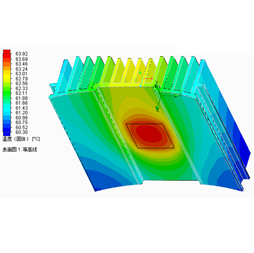

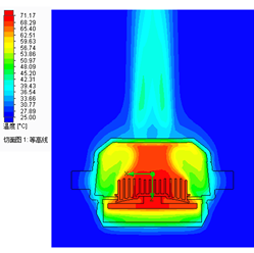

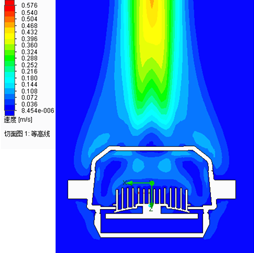

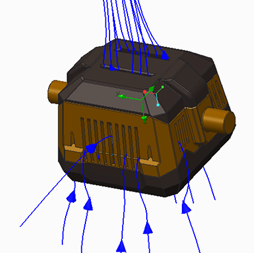

(Ambient temperature:25℃,Chipset power:24W�,Maximum temperature on the heat sink: 63.92℃)

Even if there is no specific airflow speed requirement, it is still feasible to realize the cooling of a product by using natural cooling heat sinks which are made by copper-aluminum cooling plates, aluminum extruded parts, machined parts or die-casting alloys.

Even if there is no specific airflow speed requirement, it is still feasible to realize the cooling of a product by using natural cooling heat sinks which are made by copper-aluminum cooling plates, aluminum extruded parts, machined parts or die-casting alloys.